Project Spotlight: Bringing a Vintage Coke Machine Back to Life

For one of our favorite projects to date, our team has joined forces with a local enthusiast to revive a classic piece of Americana: vintage Coca-Cola machines! Accurate CNC Services has developed a reputation for saying YES to projects other shops turn down, and this project is a great example of our passion for a challenge.

Here’s how the project landed in our shop and what we’re doing to help our customer prepare for production.

The Spark of a New Challenge

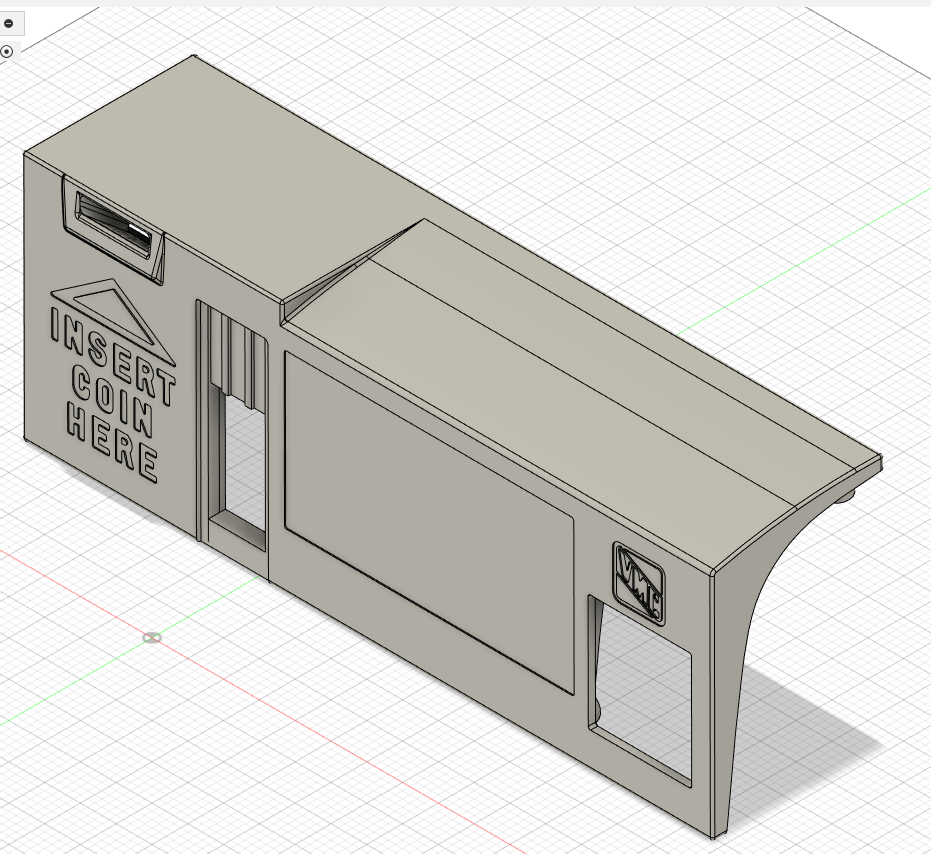

Vintage Coke machines may be relics of a bygone era, but they hold a special place in the hearts of collectors and historians. One of those enthusiasts is local to our Idaho machine shop. He contacted Accurate CNC Services for help developing a replica part for production: the machine’s iconic coin slot section.

On vintage machines, these cast, chrome-plated pieces are often worn and cracked and must be replaced. But to produce several hundred a year, our customer wanted to avoid the high price of casting and chrome plating and instead develop a machined and polished coin slot section.

The complexity of these highly visible parts lies in their impossible-to-machine square corners—easy enough for cast parts but not so achievable through precision machining. So, we took on the task of 3D scanning the original coin slot section and significantly modifying the 3D CAD model for easier machinability at a reasonable price to our customer.

Original Coin Slot:

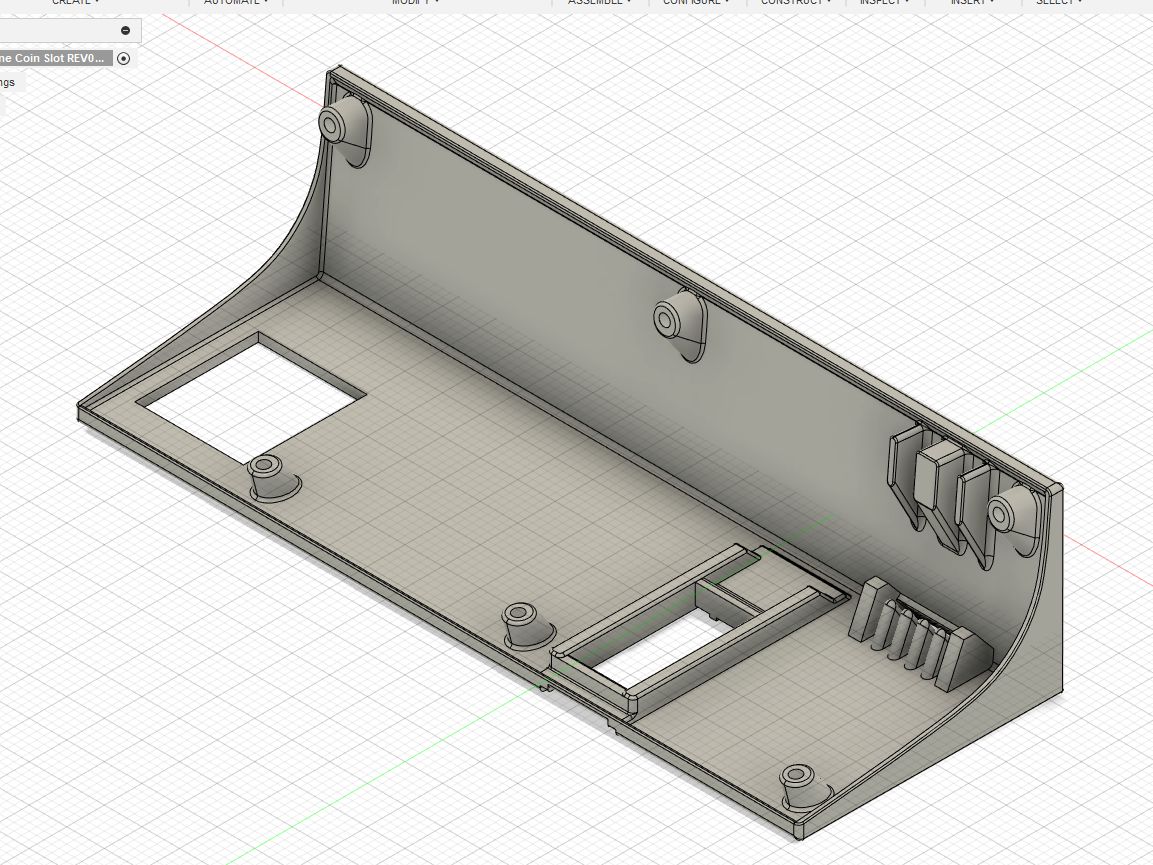

New Coin Slot:

Aesthetics, functionality, and affordability

Our customer’s vision called on us to balance three key goals:

Maintaining the vintage aesthetic

Ensuring the functionality of the coin slot

Staying within a reasonable budget

Our customer explicitly asked that each vintage machine’s exterior appear as identical as possible to the original, but he gave us the liberty to modify the part’s interior for easier precision machining. Essentially, we had to simplify the interior design while maintaining the integrity of the exterior design.

This project is a testament to the power of compromise and collaboration. Both our team and our customer have had to remain flexible to set priorities and develop the optimal solution.

Choosing the right material

Deciding on the material is another critical step—one we’re still working through. Replicating the original, chrome-plated cast parts without casting or chrome plating is a big challenge, but we’re determined to deliver. We’re currently considering polished aluminum or buffed stainless steel for final production. We’re leaning towards aluminum for its machinability and finish potential.

Once the design is complete, we’ll move to prototype machining services, making the part in a low-cost plastic to resolve any issues before transitioning to the final material. This step will help us ensure that the final product meets our customer’s criteria, from aesthetics to functionality.

Our CAD services at work

This project has also tested the limitations of our shop’s CAD services, a relatively new offering at Accurate CNC. Modifying the 3D model for better machinability has been a learning experience for us. As we’ve worked to expand our skills and improve our 3D modeling technique, our customer has benefitted from quite a bit of complimentary CAD time!

American Manufacturing for an All-American Product

The Dr. Pepper machine has the Accurate CNC coin slot while the Pepsi-Cola machine has the original.

This project goes beyond just manufacturing a part; it’s about bringing a piece of history back to life. By precision machining this coin slot section, we’re helping to restore a symbol of American culture, a task that feels particularly relevant to our team of American manufacturers. Problem-solving to achieve the best possible outcome for our customer is an enormous honor—and really fun!

As we continue to navigate the details and challenges of this project, our excitement only grows. It’s projects like these that remind us why we love what we do. We’re not just machinists; we’re creators, problem-solvers, and now, part-time historians, helping to preserve the legacy of the past generations.

Bring your project to our team, and we’ll problem-solve with you, too! Request a quote.