UHMW: The Thermoplastic with a High Strength-to-Weight Ratio

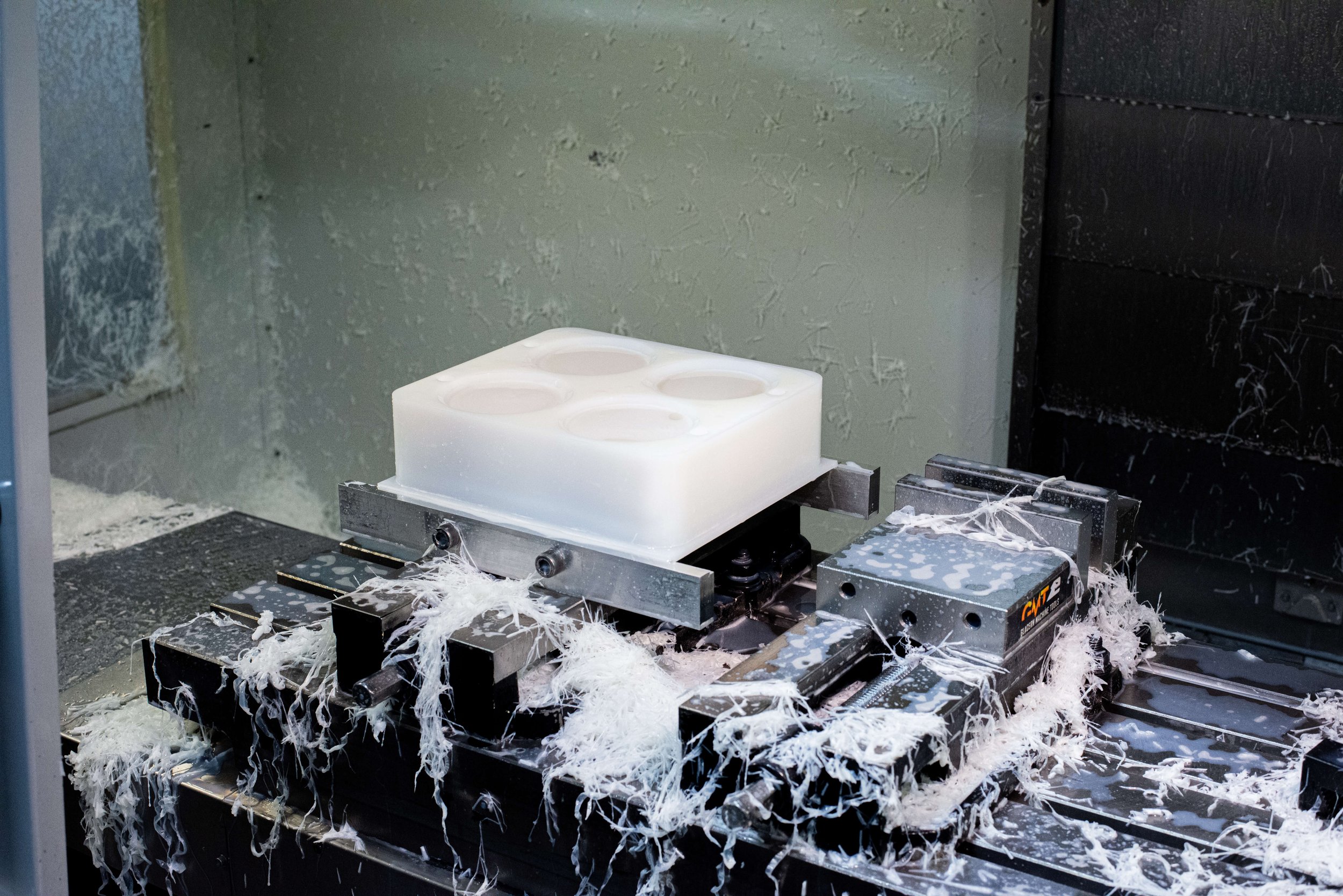

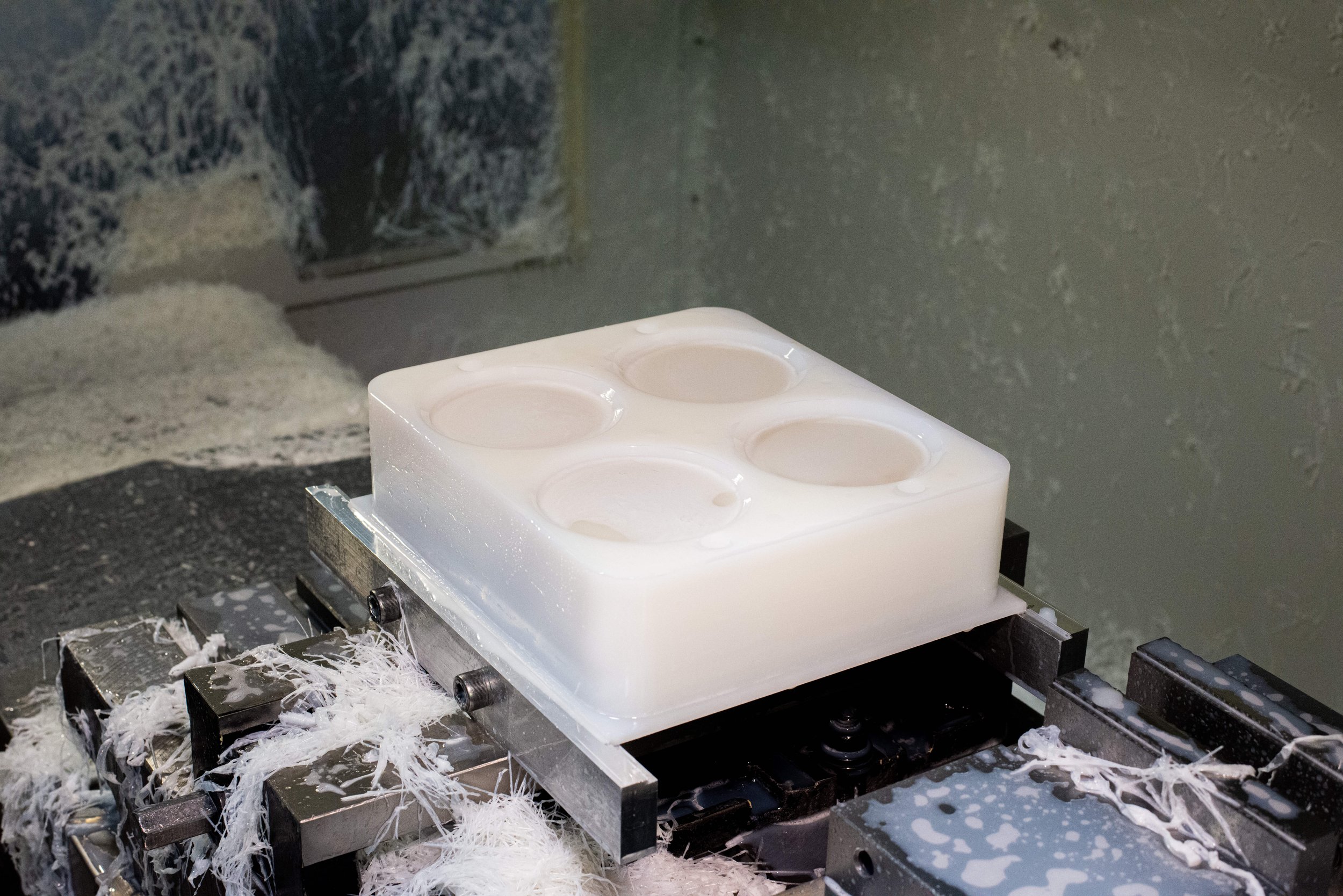

We’re big fans of UHMW polyethylene at Accurate CNC Services. Our precision machine shop frequently works with this biocompatible thermoplastic, and we’d love to help you leverage the unique properties of UHMW for your next plastics project!

What Is UHMW Polyethylene?

Simply called “UHMW” by manufacturers, UHMW stands for “ultra high molecular weight.” This polyethylene’s fibers are some of the strongest—yet lightest—you’ll find.

UHMW is available in sheets, rods, strips, and tubes. Our plastic machining services department stocks black and white UHMW sheets in thicknesses from 0.125” to 2”. We can purchase thicker sheets if your project calls for them. Reprocessed UHMW is available for customers who don’t mind the green and blue flecks common in the eco-friendly option.

What Are Common Applications for UHMW?

Because UHMW is affordable and easy to machine, it’s used in a wide range of commercial and industrial applications.

UHMW is durable and strong enough for use in chain guides, gears, bearings, and guard rails. It’s lightweight enough to serve as body armor, and its biocompatibility lends to its use in prosthetics and body implants. Abrasion-resistant and moisture-resistant, UHMW is an excellent choice for boat docks, snowplows, and truck bed liners.

What Sets UHMW Apart?

UHMW’s “ultra-high molecular weight” starts at 3.1 million grams per mole, which explains the material’s durability and impressive resistance to corrosion, wear, impact, and cold.

When you choose UHMW for plastic machining services, your parts benefit from these mechanical properties:

Tensile strength (ultimate): 2,030 - 102,000 psi

Flexural strength (yield): 2,000 - 5,800 psi

Compressive strength: 580 - 12,000 psi

Though UHMW is a thermoplastic, its fibers aren’t as heat-resistant as other high-strength thermoplastics. This self-lubricating material does melt between 291 degrees Fahrenheit and 306 degrees Fahrenheit and isn’t recommended for environments with sustained temperatures above 176 degrees Fahrenheit. UHMW is better known for its resistance to extremely cold temperatures, but it does become brittle when the thermometer drops below -240 degrees Fahrenheit.

Perhaps most impressively, UHMW’s strength-to-weight ratio is 8-15x greater than steel!

UHMW: A Tip Regarding Tolerances

Because UHMW is used for high-wear parts, tight tolerances are rarely part of the equation. However, UHMW has a surprisingly high thickness tolerance—approximately 10%! In fact, we’ve seen 2” thick UHMW sheets shrink or expand by as much as 0.25”!

Before bringing UHMW inside for plastic machining services, we always allow the material to acclimatize to our shop environment to help mitigate any temperature-related size changes. Even so, you should keep the material’s thickness tolerance in mind and design your UHMW parts with room for movement.

Get UHMW Parts at Accurate CNC Services

Not every precision machine shop is familiar with UHMW, but here at Accurate CNC, it’s commonly our top pick for parts requiring plastic machining services! If you’re unsure which thermoplastic to choose for your plastic parts, talk to our team, and we’ll help you make the best selection for your application.